Скачать с ютуб How it Works: Circumferential Piston Pump в хорошем качестве

Скачать бесплатно How it Works: Circumferential Piston Pump в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно How it Works: Circumferential Piston Pump или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон How it Works: Circumferential Piston Pump в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

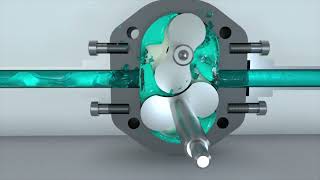

How it Works: Circumferential Piston Pump

Have questions? We'd love to chat! Send us a message here: https://www.vikingpump.com/yt In this video, you'll learn what causes a circumferential piston pump to move liquid through a process. Visit vikingpump.com for more videos! #VikingPump #CircumferentialPiston #HowItWorks ▬ More Videos ▬▬▬▬▬▬▬▬▬▬▬▬ ► YouTube Community: / vikingpumpinc ► All Viking Pump Videos: / vikingpumpinc ► Subscribe to Viking Pump Channel: https://bit.ly/2KJGmJT ▬ Social Media ▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬ ► Facebook: / vikingpump ► LinkedIn: / viking-pump ► Website: http://www.vikingpump.com One of the most common pump types in the food and pharmaceutical industry is the circumferential piston pump. Viking’s line of hygienic pumps by Wright Flow Technologies includes circumferential piston pumps, with model sizes and designs to cover a wide range of pumping applications and hygienic requirements. Despite their name, circumferential piston pumps are more similar in pumping action to external gear pumps than piston pumps. Like a gear pump, 2 pumping elements, called rotors, rotate in a close-fitting housing. Although in this design, the rotors are not in contact. The rotors are driven independently on 2 rotating shafts. A pair of external timing gears ensure that the rotors do not contact. As the rotors rotate, a cavity is formed at the inlet side of the pump. This creates vacuum to pull the liquid into the spaces between the tips of the rotor. This liquid is trapped between the rotor and the close-fitting casing wall. The rotation of the rotors carries the liquid around to the outlet side of the pump. The tight clearance between the outside of the rotor and the hub of the other rotor ensures that liquid does not pass between them. At the outlet, the reduction in size of the pumping cavity forces the liquid through the outlet port. Because of the large pumping cavities and non-contacting design, these pumps are ideal for the gentle handling of both thin and viscous liquids and liquids containing large solids. They are designed to be easily cleaned, making them ideal for applications requiring sanitary construction and frequent cleaning.