Скачать с ютуб Construction Steps of a House в хорошем качестве

Скачать бесплатно Construction Steps of a House в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Construction Steps of a House или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Construction Steps of a House в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

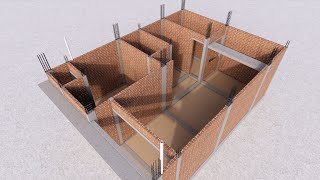

Construction Steps of a House

gooseBerry media presents..... This video is about: Step by step Construction of a building in Kerala, India It includes: Detailed plan like architectural plan, structural plan, sections, drawings of beams, columns, foundations, measurements of rooms. Model of the house - 3 storeyed building with cellar floor, ground floor and first floor. Site clearance, uprooting trees, Site clean up, levelling soil, site videos. Setting out of a building-using centre to centre distance plan, ropes, measuring tapes, cross staff, peg, plumb bob etc Construction of house foundation: Setting out foundation, Marking of house foundation excavations, Excavation in construction (digging) using JCB, Hitachi 20, transporting vehicles like tipper, Mazda etc., cleaning by workers. Column Footing construction: Footing with one column, Footing with 2 columns, Footing marking, Footing reinforcement. Building Material and construction lectures: Cement bags- we used ordinary Portland cement Metal or coarse aggregate = 4 centimeters or one and half inch and 2 cm or three by four inch River sand or washed msand or fine aggregate. Aggregate grades, aggregate consumption. Water added in accordance with water cement ratio... water/cement ratio, w/c ratio Concrete mixer fixed on the ground, Cement mixing, aggregate mixing, water mixing, mixed uniformly, mixer rotate, mixer unload to below plate sheet, Cement mix ratio. Sprinkling of water before concrete. Mix taken by workers using shovels and bowls. Concrete is placed in excavations for base concrete. Man enters excavation and spread the mix using hoe, up to the level, jammed well using jammer. By this base concrete is completed. The next structure is the reinforced cement concrete structure- RCC. For that steel rods of different dimensions are arranged. 8 mm diameter tmt steel, 10 mm dia steel, 12 mm dia, 16 mm dia steel rods are used. Reinforcement learning, Reinforcement detailing, Rcc beams and columns. Steel cut using steel cutting machine Steel mat preparation for rcc using 12 mm dia bars Stirrup making= 8mm dia, steel bending, for connecting pillar steels, use of binding wires –msw, span of frameworks, spacing. Cement sand paste applied on base concrete, marking above it on intersection of rope. Points where steel framework rest marked using chalk. Mat rest upon cover block or stones, Mat fixing. Piller framework (column framework )= 12 mm dia steel rods with stirrups, with bottom legs. It is accurately placed in marked points, legs are tied. Rcc is interconnected. Formworks laid using sheets or woods, nails, hammers. Verticality of pillar is checked using plumbob, fixed in position. Cross checked. Concrete of RCC structure =RCC square or rectangular prism + RCC taper or trapezoidal prism 20 Centimetre Rcc square, 35 cm Rcc taper. Concrete mix is placed, Mechanical vibrator is applied, and it helps in consolidating concrete. And settles firmly. Levelled. Again concrete poured, uniformly spread using floats and trowels. Rcc completes. This shape good for proper transmission of load. Water Curing or watering of concrete – very important step prevents moisture loss, maintaining favourable temperature for hydration to occur in concrete, prevents surface cracking. A small shoe is constructed above rcc taper. Shutter of the shoe is fixed and is concreted. After that the formworks of small pillar is fixed and tightened on the shoe. Small pillar is the pillar between Rcc trapezoid and the Beam belt. Watered properly, concrete poured, compacted very well using rods. On next day formwork is removed. Level ground, soil movement from and to land, soil jammed. Cement sand paste applied on place of upcoming plinth beam Plinth beam construction Steel framework of plinth beam = 3 no. of 16mm dia bar at top, 3 number of 16mm dia @ bottom, stirrups 18cm c/c distance. It is 30cm x21cm beam It rest on cover block, formwork is made, verticality of formwork checked, watered well, concreted. Vibration for good settlement, levelled using float. Completes. laid steels for upcoming pillars and retaining wall. Woks completed up to plinth beam level. This House construction video also includes, house construction techniques, buildings structures, house building tips, house building ideas etc. Send your opinions and suggestions to my email id: [email protected] Work in progress will be updated. Thank you.