Скачать с ютуб Introduction to VRF Technology в хорошем качестве

Из-за периодической блокировки нашего сайта РКН сервисами, просим воспользоваться резервным адресом:

Загрузить через ClipSave.ruСкачать бесплатно Introduction to VRF Technology в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Introduction to VRF Technology или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Introduction to VRF Technology в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Introduction to VRF Technology

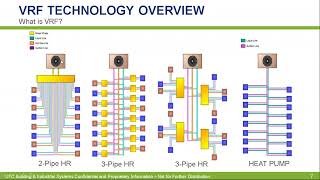

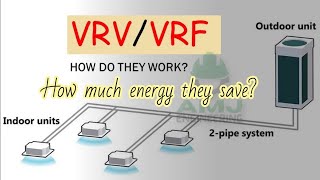

This introduction to VRF technology class from the HVACR Training Symposium was taught by John Chavez. John explains the basics of how VRF technology works and why people might want to use it in commercial structures. The adoption of VRF technology is regulated by ASHRAE. VRF heat pumps are capable of some extraordinary feats, including achieving 100% cooling capacity down to -10 degrees and 78% heating capacity down to -15 degrees. The software that controls the HVAC system is the heart of VRF technology; the software controls the refrigerant flow throughout the structure, which adjusts the HVAC system performance. VRF and VRV technology are the same thing; VRV is just a marketing term used by one company, and it means “variable refrigerant volume” instead of “variable refrigerant flow.” As with all heat pumps, VRF heat pumps have indoor and outdoor coils that can reverse their functions depending on the operating mode (heating or cooling) via a reversing valve. Modulation is also an important function in VRF technology, as they have stepper motors that control EEV, compressor (inverter-driven scroll), and fan operation. The variable-speed compressor satisfies a wide range of load requirements while saving energy. VRF systems also appear as ductless 1:1 systems, have multiple zones (up to 8:1), and come in single-phase and three-phase varieties. VRF technology architecture consists of a central controller that connects to an outdoor unit, which then connects to a remote controller and one or multiple indoor units. All units share the same system control and refrigerant charge, and they may contain heat recovery systems. A heat pump with heat recovery differs from a typical VRF heat pump in that it has an extra component: a heat recovery box. Systems with heat recovery may have two-pipe or three-pipe systems and can perform simultaneous heating and cooling. (The two-pipe configuration is standard for regular heat pumps.) Algorithms control VRF technology by assessing the conditions and telling the equipment to operate a certain way based on those conditions. Whereas many heat pumps have difficulty providing heating in cold temperatures, VRF heat pumps optimize several parts of their system to allow the system to heat efficiently and effectively. VRF technology allows you to mix and match indoor units, use a flexible piping design, and get 150% connected capacity (connecting 15 tons’ worth of indoor units to a 10-ton outdoor unit). However, you must know your building profile (diversity) before making use of connected capacity effectively. VRF designs tend to be flexible and can have their controls easily manipulated by DIP switches. The compactness and economic nature of VRF systems also make them attractive due to their small footprint, low energy consumption, quietness, and cost-effectiveness. The variable-speed compressor allows VRF systems to match part-load conditions and regulate the discharge temperature for maximum compressor longevity. Lower electrical loads allow compressor startup to be relatively soft, as there is no inrush current. A variable-speed compressor also tends to have a high power factor and low reactive power, making it energy-efficient and able to handle precise temperature control without high kWh usage. In many cases, warranty returns are also very low, meaning that VRF systems are also beneficial to contractors. These systems also tend to be less expensive to operate and maintain over time than conventional HVAC systems. VRF systems use a remote controller to manage the set point for the indoor unit. These controllers are more complex than thermostats, as they can also control vanes and other parts of system operation. The outdoor unit works as a function of the connected capacity, thermistor readings, compressor hertz, LEV position, and pressure and temperature targets. The voltage gets converted from AC to DC, smoothed, and then back to AC power between the control section, microcomputer, and compressor. The system can also manipulate the cycles per second (hertz or Hz) from the power supply to match the equipment. PID (proportional, integral, and derivative) controls continuously adjust the EEV, which allows the refrigerant flow to vary based on the changing conditions. VRF systems also use smart coil technology, which are sensors that determine target superheat and subcooling temperatures. Some VRF heat pumps also come in the water-source, ground-source (geothermal), and hybrid varieties. Indoor units can come in high-wall, ceiling-suspended, or floor-standing varieties. They also have varied ceiling cassettes with built-in drain pumps. You can download this presentation from John’s LinkedIn page at / johnkchavez . Read all the tech tips, take the quizzes, and find our handy calculators at https://www.hvacrschool.com/.