Скачать с ютуб ZMD® Air Springs: ZERO MAINTENANCE DAMPING® for Trailer Suspensions в хорошем качестве

Из-за периодической блокировки нашего сайта РКН сервисами, просим воспользоваться резервным адресом:

Загрузить через ClipSave.ruСкачать бесплатно ZMD® Air Springs: ZERO MAINTENANCE DAMPING® for Trailer Suspensions в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно ZMD® Air Springs: ZERO MAINTENANCE DAMPING® for Trailer Suspensions или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон ZMD® Air Springs: ZERO MAINTENANCE DAMPING® for Trailer Suspensions в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

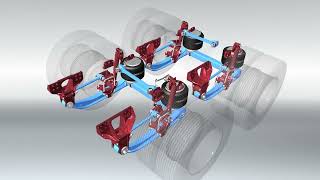

ZMD® Air Springs: ZERO MAINTENANCE DAMPING® for Trailer Suspensions

ZMD® technology eliminates shock absorbers from the maintenance equation by integrating the damping function traditionally performed by the shock within the air spring itself. ZMD air springs exchange pressurized air between the bellows and the piston. This patented air spring provides uniform and consistent damping over the life of the air spring. Available as a premium option on select VANTRAAX® and INTRAAX® integrated air suspension models and standard on ULTRAA-K® air slider systems. Learn more: http://www.hendrickson-intl.com/Trail... SUBSCRIBE to Hendrickson’s Channel: https://www.youtube.com/user/official... CONNECT with Hendrickson! Twitter ► / hend_intl Facebook ► / hendrickson.intl LinkedIn ► / hendrickson [Video Transcript] In the commercial trailer industry, managing issues like driver comfort, cargo protection, vehicle maintenance, and government compliance can be a complicated balancing act. Understanding the fundamentals of suspension damping can help fleets address these concerns. Proper damping makes the suspension less susceptible to vibration by lessening the impact of road inputs that are transmitted through the trailer. Consistent damping performance helps protect the trailer's payload, can extend maintenance intervals and replacement cycles, and may provide a more comfortable ride for increased driver satisfaction. All suspension designs, whether multi-leaf, mono-leaf, or air, provide some level of suspension damping. These types of traditional designs are susceptible to inconsistent and deteriorating damping levels over the service life. Furthermore, such designs present their own set of maintenance challenges, whether frequent re-torquing of U-bolts or maintaining an external damping device. Hendrickson addresses the inherent shortcomings of previous damping control methods with a revolutionary new approach, Zero Maintenance Damping® technology. An alternative solution for fleets seeking reduced maintenance and improved ride quality. The advanced ZMD® system eliminates the need for external damping components, such as suspension bump stops or shock absorbers. By removing the shock absorber, a main wear item, ZMD® not only removes an underlying cause for damping degradation, but also its subsequent maintenance requirements. This unique air spring performs the damping function by exchanging pressurized air through sealed channels that interconnect the bellows and piston. Additionally, unlike a leaf-spring or shock absorber, whose damping capacity is finite and deteriorates with age, ZMD® air springs are designed to provide continuous and consistent damping rates for the life of the air spring. This enhances the suspension's ability to reduce road vibrations transmitted to the trailer for a smoother, high-quality ride. Hendrickson's research shows that ZMD® technology provides superior suspension damping for improved driver comfort and cargo protection. ZMD® helps reduce the risk of CSA violations due to damaged or worn shocks, which could potentially sideline a trailer at an inspection. Hendrickson's revolutionary new approach to damping control addresses the shortcomings of previous methods and offers fleets an innovative solution to help lower maintenance and enhance ride quality, compliance, and driver satisfaction. Hendrickson ZMD®. Zero Maintenance Damping® shockless ride technology.