Скачать с ютуб Laminate Sample #1: Light Carbon Fiber on 9mm Nomex - Vacuum Bagged Epoxy Wet-layup в хорошем качестве

Скачать бесплатно Laminate Sample #1: Light Carbon Fiber on 9mm Nomex - Vacuum Bagged Epoxy Wet-layup в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Laminate Sample #1: Light Carbon Fiber on 9mm Nomex - Vacuum Bagged Epoxy Wet-layup или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Laminate Sample #1: Light Carbon Fiber on 9mm Nomex - Vacuum Bagged Epoxy Wet-layup в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Laminate Sample #1: Light Carbon Fiber on 9mm Nomex - Vacuum Bagged Epoxy Wet-layup

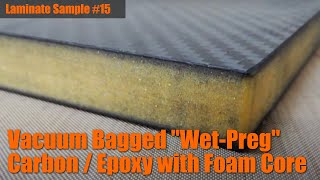

Laminate Sample #1 in the Explore Composites! Material Library: This is where the Laminate Library begins - not for any logical reason - just that I was doing some experiments and though I'd make a video about a basic but unusual type of test panel. It seemed like a useful format and I figured it would give me a chance to show the simplest kind of part across a wide variety of materials and processes. Being able to compare weights is useful too. This is actually kind of a strange way to build a part, but it is interesting and shows some fancy core used simply. Honeycomb is hard to buy but can often be found surplus on Ebay and other places for cheaper than foam or balsa. Check out Laminate Sample #15 for more on how to do this more elegantly but with more work: • Laminate Sample #15: Vacuum Bagged "W... And see Laminate Sample #12 for how to do this with pre-preg: • Laminate Sample #12: Light Prepreg Ca... ...and #16 for how to do this with pre-cured sheets of material. Details: This is 200g (6oz) woven carbon laminate wet-laminated with 9mm Nomex honeycomb core in two separate curing/vacuum bagging operations. Resin is Totalboat 5:1 Epoxy from Jamestown Distributors with room-temperature cure. The goal is to have a light wet-laid panel with thick enough core for large unsupported areas. Cold room temperature (55F - basement in the winter!) reduced resin viscosity. Also not ideal resin for this. Honeycomb doesn't apply consistent pressure on carbon to force out air. Surface turned out very pin-holey and not ideal. Also tried very hard to use minimum resin to wet out carbon. Rolling with a wetout-roller would have helped too! Will try it again next summer! See the rest of the information at: https://explorecomposites.com/materia...

![COOK Stickers in CARBON FIBER mould to 120 Degrees C [PREPREG CARBON FIBRE] How To Make Carbon Fibre](https://i.ytimg.com/vi/0cTlp7Y_ess/mqdefault.jpg)