Скачать с ютуб 6 Basic Rules Of Centrifugal Pump Piping в хорошем качестве

Скачать бесплатно 6 Basic Rules Of Centrifugal Pump Piping в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно 6 Basic Rules Of Centrifugal Pump Piping или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон 6 Basic Rules Of Centrifugal Pump Piping в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

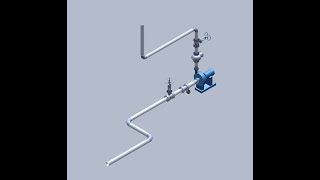

6 Basic Rules Of Centrifugal Pump Piping

6 Basic Rules Of Centrifugal Pump Piping 6 basic rules of centrifugal pump piping to achieve the best pump performance The 6 Rules of Centrifugal Pump Piping are as below, 1 Adequate Straight Pipe Length Before the Pump Inlet: Imagine the straight pipe length as the opening act of a fluidic ballet, setting the stage for a graceful performance. Just as in dance, where disruptions like elbows and valves can lead to turbulence, a sufficient straight run becomes the choreographer's tool to minimize these disturbances. This ensures that the fluid entering the pump pirouettes smoothly, a crucial dance for efficient pump operation, gracefully avoiding cavitation missteps 2 Size the Suction Pipe Appropriately: Consider the sizing of the suction pipe as the conductor's choice in an orchestral symphony, dictating a harmonious flow. Much like a musical crescendo, opting for a larger size slows the dance, preventing turbulent notes and preserving the symphony of Net Positive Suction Head (NPSH). This ensures the pump's virtuoso performance without the disruptive crescendos of cavitation. 3 Avoid High-Velocity Suction Piping: Envision fluid velocity as a waltz, a dance partner gracefully treading the delicate steps in the suction ballet. Much like a dance choreography that restrains its tempo, maintaining a waltz-like fluidic pace avoids the risk of turbulent tangos. This preserves the pump's serenade, ensuring it dances through its operation without the discordant notes of cavitation calamities. 4 Minimize Elbows and Fittings in Suction Piping: Picture the suction minuet as an elegant dance, where elbows and fittings pirouette delicately. Each step introduces a note of turbulence, and a pas de deux with minimal disruptions ensures a graceful flow. This fluidic ballet sidesteps cavitation missteps, allowing the pump's melody to echo undisturbed in a performance of fluidic grace. 5 Provide Adequate Support for Piping: View piping as a silent cantata, with support acting as anchoring maestros orchestrating stability. Fluidic vibrations, like disharmonious notes, threaten to mar the symphony. Anchors and supports play the role of silent maestros, ensuring stability, harmonizing the pump's cantata, and preventing cacophonies of wear and misalignment in the fluidic ensemble 6 Include a Discharge Check Valve: In the discharge rhapsody, a check valve emerges as the final harmonic assurance, a note of certainty. Absent this coda, the pump, a virtuoso at rest, risks an encore in reverse. Water hammer, a percussion of discord, is stilled by this final note, ensuring the pump's magnum opus remains undisturbed in a fluidic rhapsody. @engineeringfacts1 @EngineeringinHindi55 Thumb rule for centrifugal pump, adequate piping support, vibrations in pump systems, pump alignment, check valve importance, backflow prevention, water hammer mitigation, fluidic ballet in pumps, pumping system stability, piping configuration, efficient pump operation, pump maintenance tips, piping design principles, Net Positive Suction Head (NPSH), fluid flow control, pump reliability factors, suction pipe best practices, preventing pump cavitation, smooth fluid entry, pump system guidelines, anchoring piping for stability, pipe length before pump inlet, suction side optimization, fluidic symphony in pumps, pump efficiency tips, fluidic choreography, pump system integrity, piping support techniques, pump inlet dynamics, efficient pump suction, suction pipe configuration, check valve in pump discharge, why Suction line diameter is bigger than discharge line diameter? • Why suction line diameter is bigger t... Rotameter working principle • Rota Meter Flow meter For Flow Measur... Packed column vs Tray Column 👇 • Packed columns VS Plate columns | bac... Pressure Drop Calculation in pipe with example 👇 • Pressure Drop Calculation In Pipe wit... Blowdown in Boiler 👇 • Blowdown In Boiler Animation Line Sizing Calculations with example 👇 • Line Sizing Calculations with Example Cooling Tower Working Animation • cooling tower working animation @engi... shutt off Pressure of pump 👇 • Shutt off pressure of pump | Shutt of... join our Facebook group "chemical engineering world 2 " 👇 https://www.facebook.com/groups/27783... Like our Facebook page👇 / chemical-engineering-world-guide-101246018... chemical engineer online Facebook group👇 https://www.facebook.com/groups/22591... #centrifugalpump #piping #cad