Скачать с ютуб Very Fast Automated Design and Manufacture of Profile Plastic Extrusion Tools and Dies at NJPT в хорошем качестве

Скачать бесплатно Very Fast Automated Design and Manufacture of Profile Plastic Extrusion Tools and Dies at NJPT в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Very Fast Automated Design and Manufacture of Profile Plastic Extrusion Tools and Dies at NJPT или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Very Fast Automated Design and Manufacture of Profile Plastic Extrusion Tools and Dies at NJPT в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Very Fast Automated Design and Manufacture of Profile Plastic Extrusion Tools and Dies at NJPT

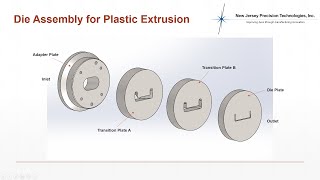

This demonstration is of automated design and manufacture of Profile Plastic Extrusion Tools at NJ Precision Technologies: ****************************************************************************************************** LINK TO LEARN MORE ABOUT AUTOMATED DESIGN AND MANUFACTURE OF PLASTIC EXTRUSION TOOLS: https://www.njpt.com/plastic-extrusio... ****************************************************************************************************** Transform your plastic extrusion business with custom tooling from NJ Precision Technologies, Inc. New Jersey Precision Technologies offers very fast delivery of profile plastic extrusion tooling for all industries. Find us at www.njpt.com. We use State-Of-The-Art custom software systems coupled with massive amounts of automated CNC Equipment. At NJPT, our 45+ Wire & Sinker EDM machines and dozens of CNC Mills and CNC lathes are running 24 hours per day, 7 days per week. Our custom Plastic Extrusion design software allows your product to be tooled-up amazingly fast. Watch how our engineers design the entire tool package with all programs in a matter of minutes. The talented engineers at New Jersey Precision Technologies have developed an automated Design and Manufacturing system to allow us to help you bring your Plastic Extrusion Profiles to market faster than ever before. This system enables our engineers to interactively design, program and build Plastic Extrusion Tools faster than dreamed possible. Your Plastic Extrusion Machines need custom extrusion tools, designed and built right, the first time, so you can get you products delivered on time, every time. Watch how we do this using this automated software system. The demonstration will be of a typical extrusion tool set of an assembly of 3 separate plates needed to create a unique, rigid PVC plastic product profile. The adapter plate or head, lies closest to the extruder and assists the flow of plastic from the screen-pack and breaker-plate into a generic shape, such as oblong, bowtie or rectangular. Next is the middle transition plate or plates and it is where the plastic flow is separated into different sections using ribs and is presented to the final plate. The die plate or face plate is the exit plate and is responsible for shaping the plastic into its desired profile by considering all post-extrusion effects through its design. The extrusion tooling assembly is customized to allow the plastic to flow properly into all areas of the channels and to streamline the approach. This will eliminate potential burning and allows for your product design to be ready for downstream calibration. At NJPT, our engineers have developed standard design criteria and logic to design the adapter, transitions and die plates. These protocols have been validated with customer feedback and is used for every design. Engineers at NJPT have used the developed protocols and converted them into automated routines to perform plastic extrusion tool designs. The program allows the import of any extrusion profile in DXF, DWG or most any other cad format. The specifications and design parameters for each tool set are initially entered by the designer into a graphical user interface. Some of these values are obtained from the customer and some are automatically determined to parametrically identify the design for the overall design process. To ensure uniform flow of the polymer near the ends of the legs, Flares and Extensions are designed and incorporated. The program will automatically recognize the type of leg and design them in. Similarly, to ensure uniform flow across the corners, features like flow-restrictors need to be added and designed. The program automatically recognizes the corner type and adds the flow-restrictor. To improve the flow into the die plate from the transition plate, a feature called a “Lead-in” is designed. This is manufactured using a CNC Chamfer mill or Ball endmill. The program designs the Lead-in and its toolpath as well. The program then designs optimal screw hole patterns with unique layouts to add dowels, counterbores, taps and drilled holes. These are necessary to ensure that all the plates in the assembly are aligned correctly during the extrusion process. The program finally outputs all design and build drawing sheets for the Adapter, Transition and Die-plates with all elements and manufacturing data. It generates complete CNC milling and Wire-EDM programs for fully automated manufacturing of the components in record time. This system feeds into our 75 plus EDM machines, CNC Mills & Turning Centers, 24 hours a day, 7 days a week. Let us show you how New Jersey Precision Technologies can use our decades of Plastic Extrusion Tooling experience to help you be the best you can be.